Description

Used Filling Monoblock MITSUBISHI up to 39000 BPH

It is extremely important to note that this machine is complementary to it’s rinsing machine: (click here).

The Filling Monoblock Mitsubishi offers an advanced solution in the bottling sector. Specifically designed to handle a wide range of liquids, it boasts a capacity of up to 39,000 BPH.

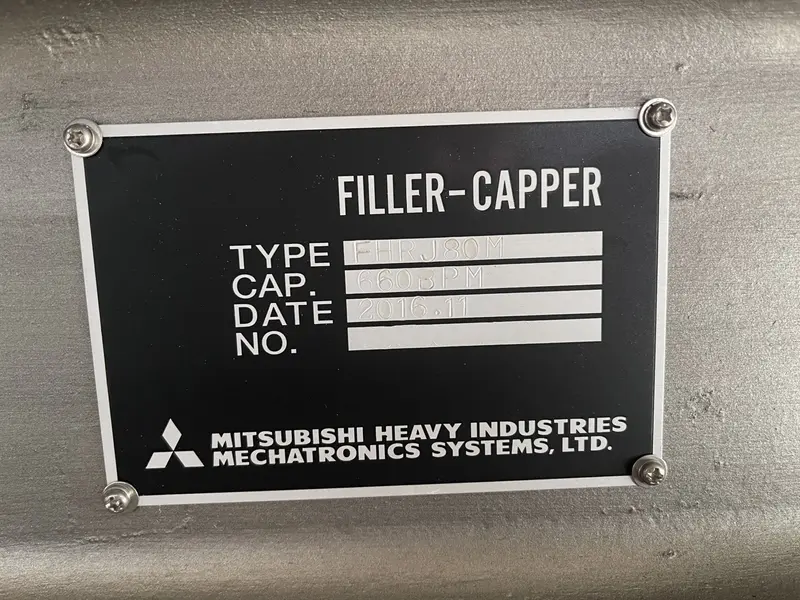

Technical Specifications of Model FHRJ80M

Mitsubishi Heavy Industries Mechatronics Systems Ltd manufactured the FHRJ80M model in 2016 to meet the growing demands for speed and precision in bottling. Equipped with 80 valves, this weight-based filling system accurately doses products, significantly minimizing waste. Moreover, the system fills aluminum bottles in various sizes ranging from 0.29L to 0.41L. Thus, it showcases its versatility for handling different types of liquids such as coffee (last product that has been filled by this monoblock), liquid soap, oil, and spirits.

Bottling and Capping Features

Furthermore, the Mitsubishi FHRJ80M monoblock integrates a capping function with 24 heads, accommodating aluminum screw caps of 28 mm and 38 mm. Its clockwise rotation direction eases integration into existing production lines. Additionally, the precision in cap placement and swift execution ensure the process’s efficiency, which is crucial for preserving product integrity and container safety during transport and storage.

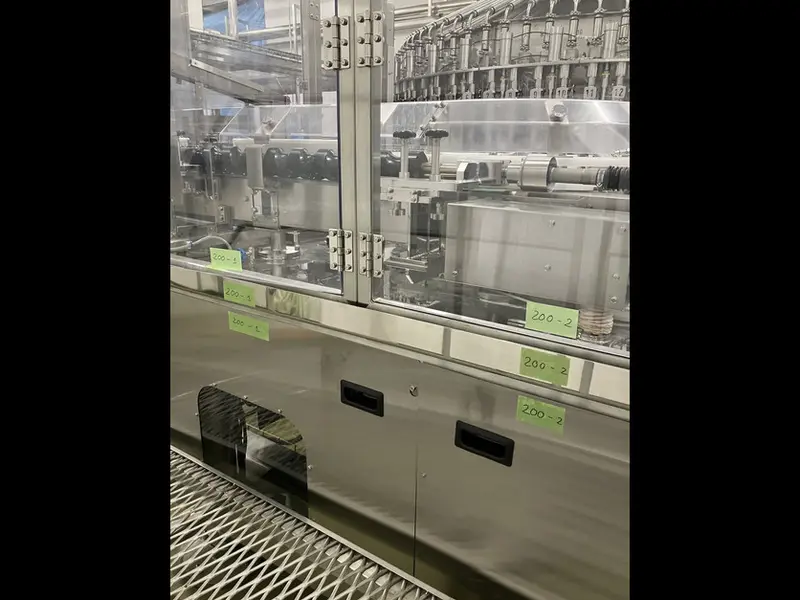

Storage and Maintenance

Currently stored in a warehouse, the Filling Monoblock Mitsubishi remains in excellent condition to ensure its functionality and readiness. Also, the availability of instruction manuals aids in maintenance and repair operations, which are essential for extending the machine’s lifespan and maintaining optimal performance. Integrated safety features protect operators and the machinery, thereby reducing accident risks during operation.

Conclusions of the Filling Monoblock Mitsubishi

Finally, the used Mitsubishi FHRJ80M filling monoblock serves as an optimal solution for those seeking efficiency and reliability in the bottling industry. Its adaptability to various formats and product types, along with the precision of its filling and capping system, make it ideal for a broad range of industrial applications. With proper maintenance and careful management, this monoblock can deliver high performance, significantly enhancing production process optimization. This model not only meets but also exceeds industry expectations in terms of functionality and performance.