Description

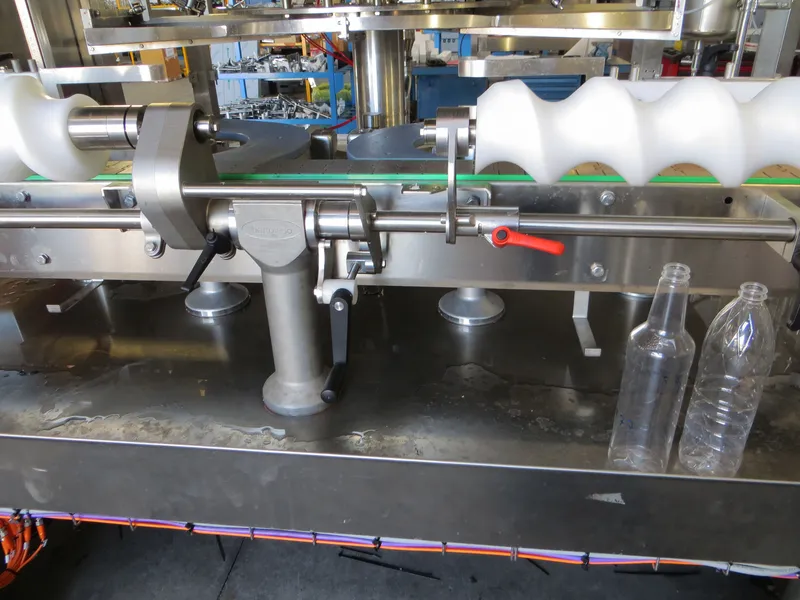

New Filling Monoblock Bertolaso 30/30/4 – PET/Glass up to 6500 bph

Notice:

Brand NEW Bertolaso monoblock, never used. Zero working hours. Pristine condition. The perfect opportunity to purchase a new monoblock at a used price.

This new Bertolaso 30/30/4 monoblock emerges as an advanced technological solution, specifically designed to optimize filling operations for syrups filling system.

Manufacturer and Model: Produced by Bertolaso, a benchmark name in the industry, this monoblock stands out for its performance and build quality. The model specification, 30/30/4, combined with its production year, 2021, provides crucial information on its current relevance in the bottling solution landscape.

Speed and Capacity: With a speed of 6500 BPH, this filling monoblock Bertolaso can handle both PET and glass containers, ensuring accuracy and consistency in the filling process.

Rinser: The rinser is equipped with 30 grippers and offers a single treatment.

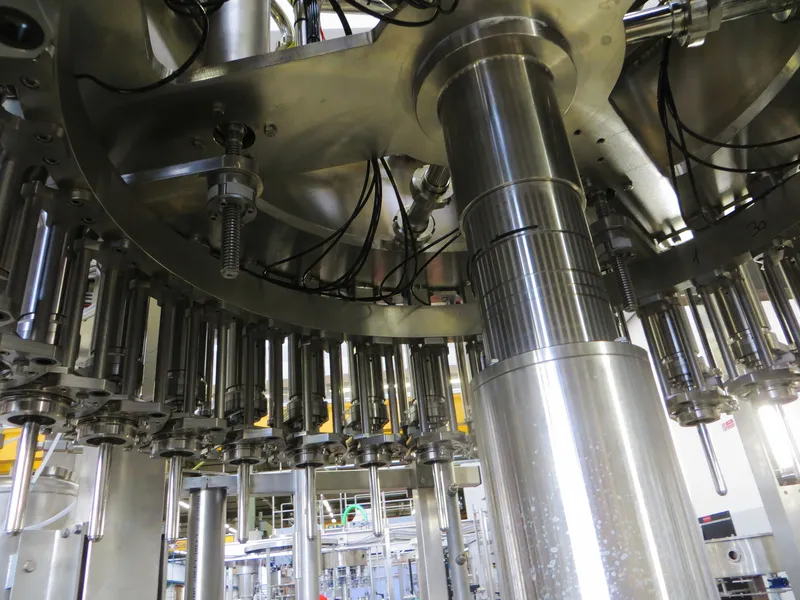

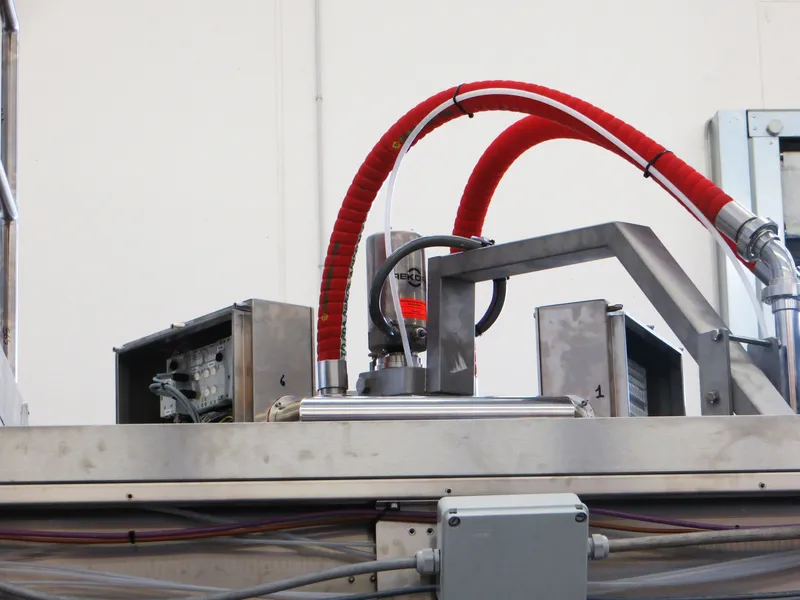

Filler: With 30 valves and a high vacuum filling system, it guarantees accurate and uniform filling of containers. The mobile nozzle highlights the filling monoblock Bertolaso’s ability to adapt to various operational needs.

Capper: The capper of the filling monoblock Bertolaso, with 4 heads, is versatile in handling different types of caps, both aluminum screw and press-on plastic. Its ability to handle caps of various sizes adds further flexibility to the monoblock.

Additional Features: Operational safety is ensured by various integrated features. The clockwise rotation direction and the electrical data (V: 380 and Hz: 50) emphasize the attention to technical details. The filling monoblock Bertolaso comes with manuals, which are essential for operators and maintenance technicians.

In conclusion, the filling monoblock Bertolaso 30/30/4 monoblock stands as a reference point for industry experts, combining efficiency, safety, and versatility. Its technical specifications speak for themselves, underscoring the importance of choosing technologically advanced solutions in the bottling arena.

TECHNICAL SPECS

Product: syrups

Bottles:

- 700 ml glass Alexanderflasche – Ø 70,1/72,1 x 291 H mm – drawing AZ-01.019.01-03

- 700 ml Flakon PET – Ø 68,5 x 272,5 H mm – drawing 1304-01-002

- 1000 ml Flakon PET – Ø 76 x 298,5 H mm – drawing 3041-01-006

- 1000 ml PET – Ø 74 x 277,4 H mm – drawing 1709-01-003

- 700 ml glass Wodka – Ø 74,6/57,2 x 304,5 H mm – drawing 2807-02W1C

- 700 ml Vodka STD – Ø 74,6/57,6 x 304,6 H mm – drawing 2597S087

Maximum bottle diameter: 100 mm

Minimum bottle diameter: 52±2 mm

Maximum bottle height: 360 mm

Minimum bottle height: 180 mm

Minimum interior neck diameter: 18,5±0,5 mm (Ø 16 mm filling valve)

Closures:

- a) pilferproof aluminum screw cap – Ø 28 x H 18 mm on bottle n. 5)

- b) pilferproof aluminum screw cap – Ø 28 x H 35 mm on bottle n. 6)

- c) pilferproof aluminum screw cap – Ø 31,5 x H 18 mm on bottle n. 1)

- d) press-on plastic cap – Ø 30 x H 20 mm on bottles n. 2), 3) and 4)

- e) pre-threaded plastic cap – Ø 30 x H 15 mm not to be handled with the present supply

- f) pilfer-proof aluminum screw cap with cylindrical pourer – Ø 31,5 x H 24 mm on bottles n. 1

- g) pilfer-proof aluminum screw cap with conical pourer – Ø 31,5 x H 24 mm on bottles n. 1

Max speeds of the filling monoblock Bertolaso: 6500bph

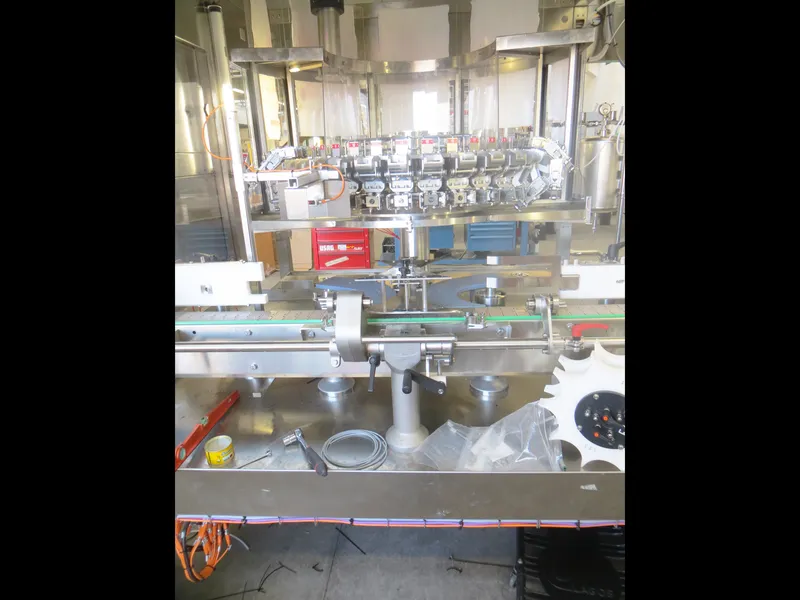

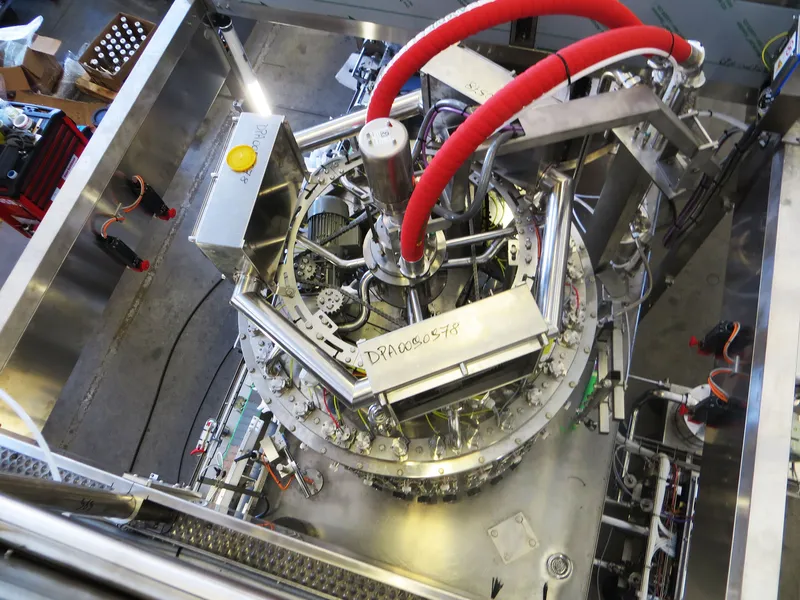

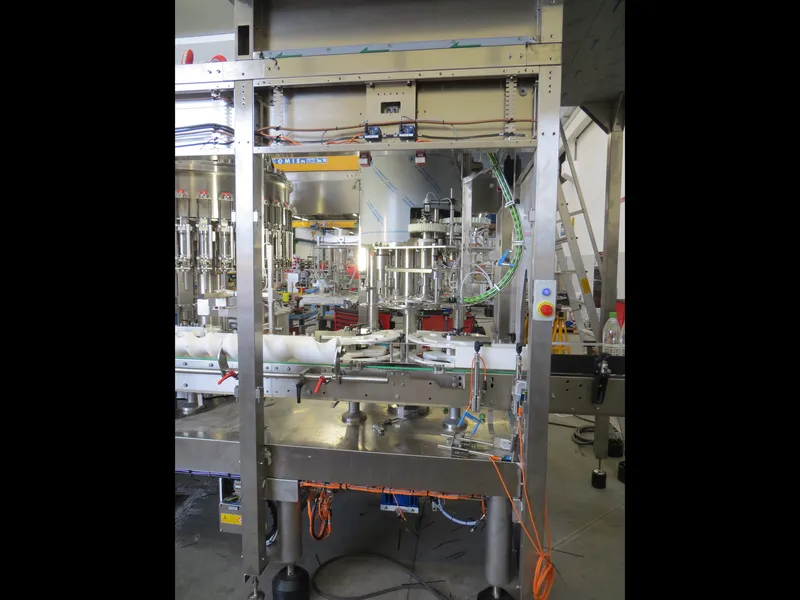

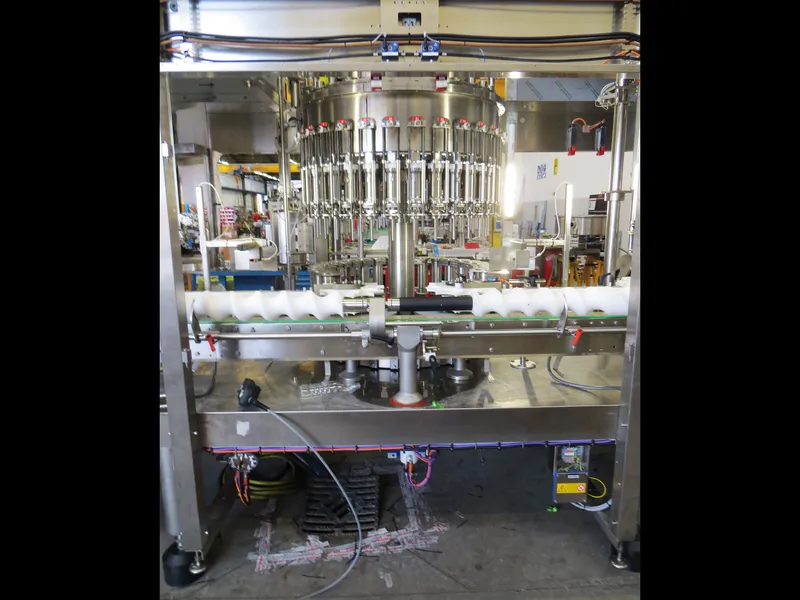

Automatic Unibloc for rinsing, filling, and capping filling monoblock Bertolaso model 30/30/4 basically consisting of:

- a) Rinser model IDRA 30/1050 with 30 fixed nozzles

- b) Filler model OLIMPIA 30/1050 with 30 filling valves for syrups filling system

- c) Capper model SIGMA/KAPPA with 4 heads to apply one size of pilferproof aluminum screw cap

Description:

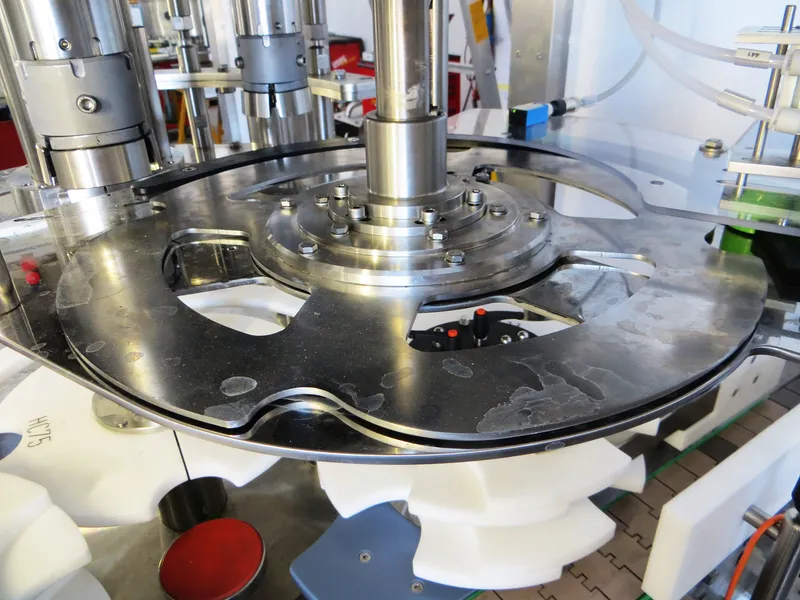

a) Automatic rinser model IDRA 30/1050 with 30 fixed nozzles.

Functional features:

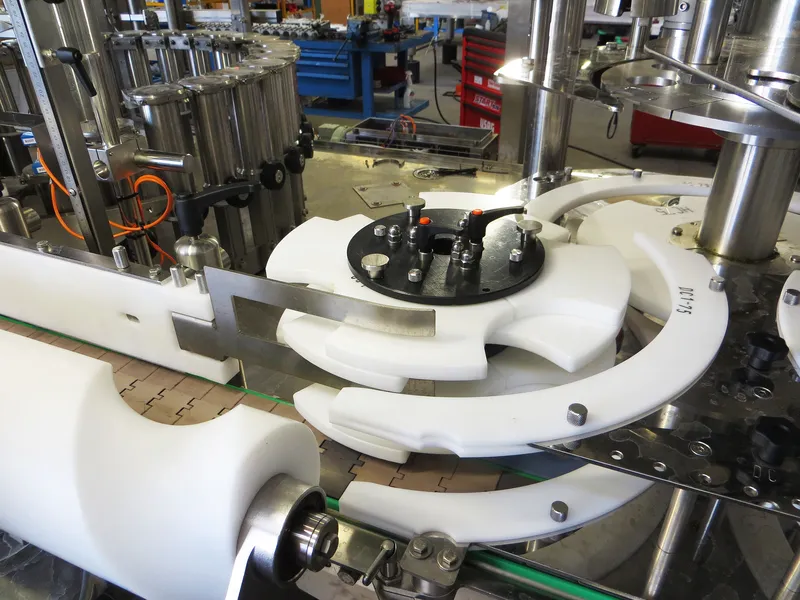

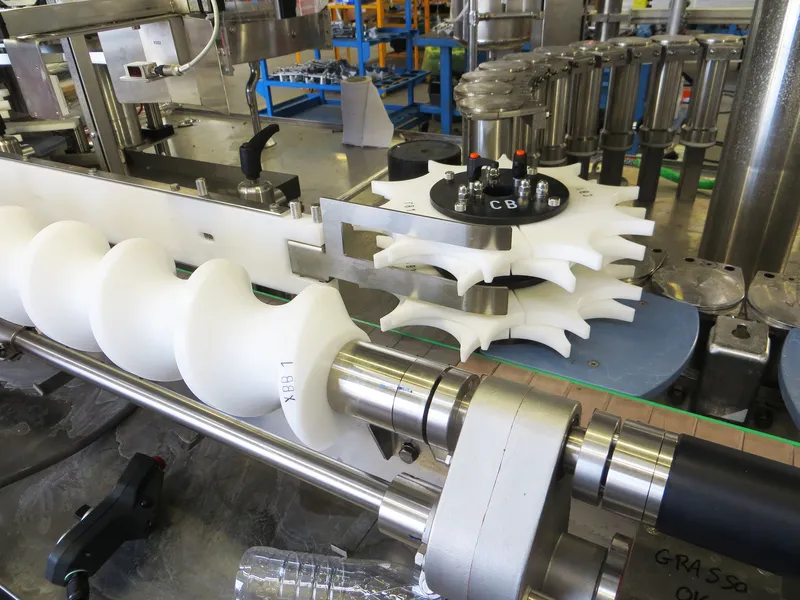

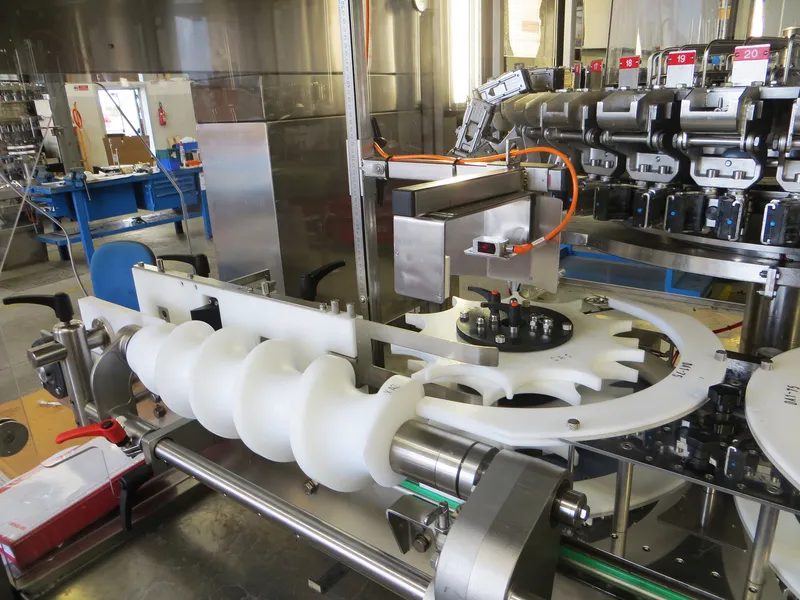

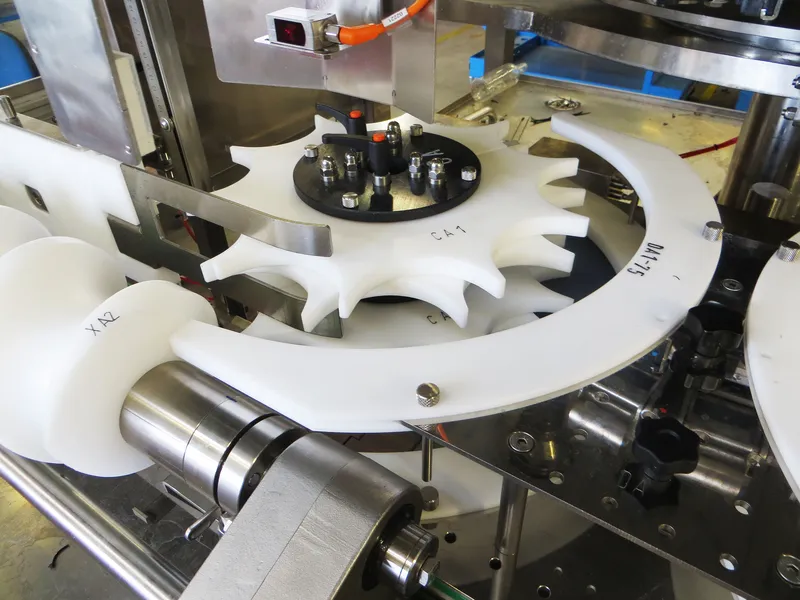

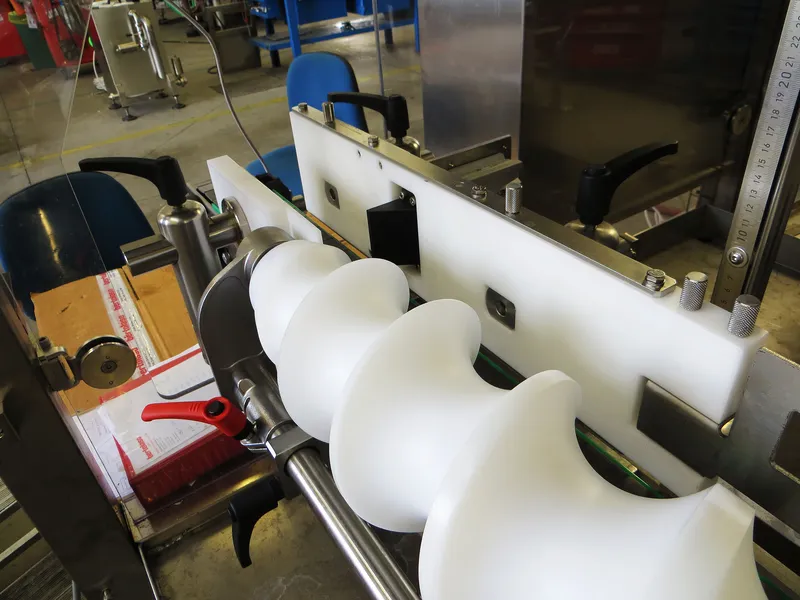

The bottles arriving at the machine by conveyor are spaced to the pitch of the machine by an infeed screw and placed by the inlet star-wheel in front of the grippers that are supported by a carrousel.

The bottles are picked at the neck and locked by two pads made of food-grade material.

In order to ensure the perfect centering even at high speeds, the bottle is picked at the neck by the gripping pads while it is still in the starwheel pocket

A helical guide then rotates the grippers so that the bottles are turned upside down with their mouths over the spraying nozzles.

At this stage, the spraying inside the bottles is actuated. The rinsing treatment occurs only when the bottle is present, thus preventing wetting outside the bottles next to the missing one.

When the rinsing treatment is complete, the bottles remain turned upside down for a dripping time sufficient to ensure the reduction of the residual liquid to a minimum quantity.

After the spraying and dripping stages, the bottles are turned again by the helical guide to the vertical position and conveyed by the starwheel toward the outlet of the machine.

Constructive features:

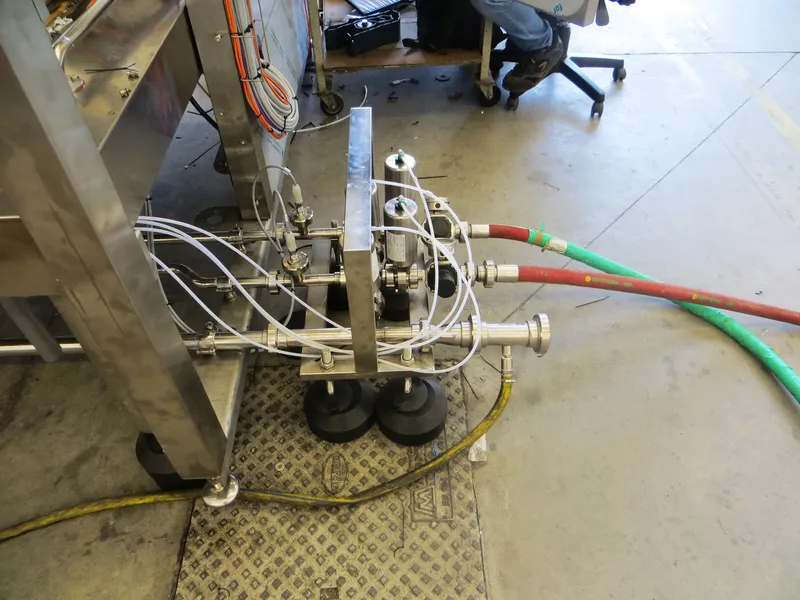

- Gripping heads in AISI 316 stainless steel with pads in food-grade material

- Spraying valves and nozzles in AISI 316 stainless steel

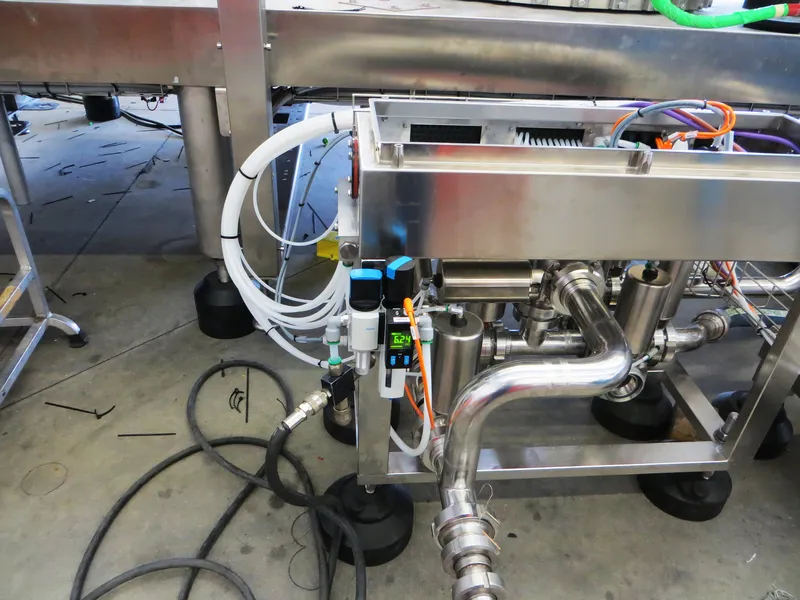

- Rinsing liquid pressure reducer reduces the net pressure to the same value as the working pressure and keeps it constant

- Safety pressure gauge stopping the machine in case of insufficient pressure of the rinsing liquid

- Closing valve of the rinsing liquid flow with the stopped machine; consequently, there is no liquid under pressure in the circuits of the stopped machine

- Electric working height adjustment

Technical specifications:

Number of grippers 30

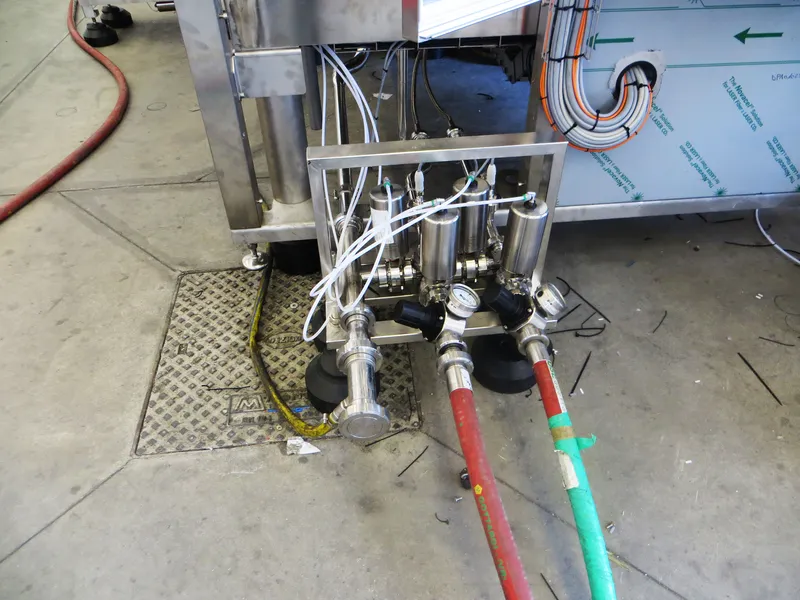

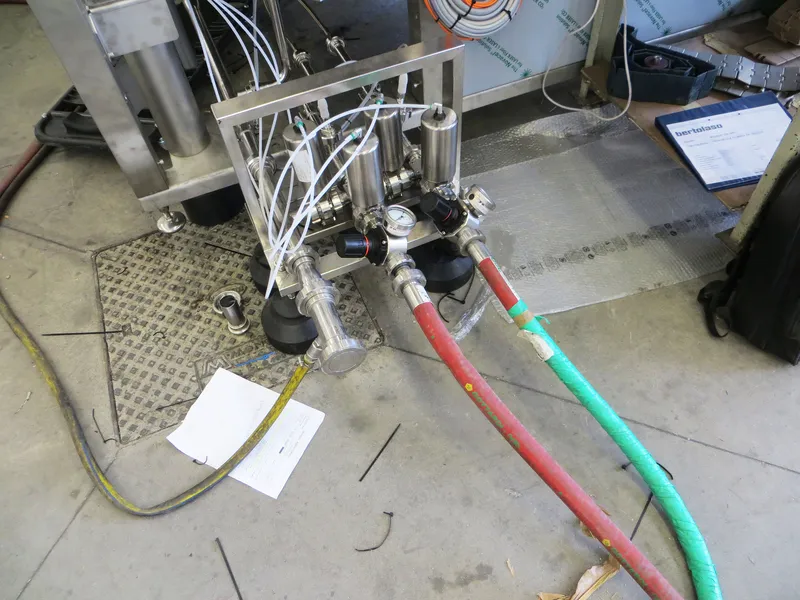

Min. liquid feeding pressure: 3 bar

Max liquid feeding pressure: 6 bar

The machine is basically composed of:

Bowl totally of AISI 304 stainless steel. All bowl surfaces are machined by machine tools and special care is dedicated to the surfaces in contact with the product that are also polished. The internal base of the bowl bottom is adequately sloped to allow the full drainage of the liquid during the cleaning cycles or bowl-emptying phase.

The lid is locked to the bowl mechanically by means of outer locking screws that are not in contact with the product. All of the above permits top-grade bowl sanitation

Filling valves totally made of AISI 316 stainless steel, machined accurately on each part to permit a controlled flow of the liquid.

The filling level in the bottle is changed by a quick adjustment.

Each part is got by machine tool processing and the surfaces are carefully finished to achieve both performance precision and sanitation

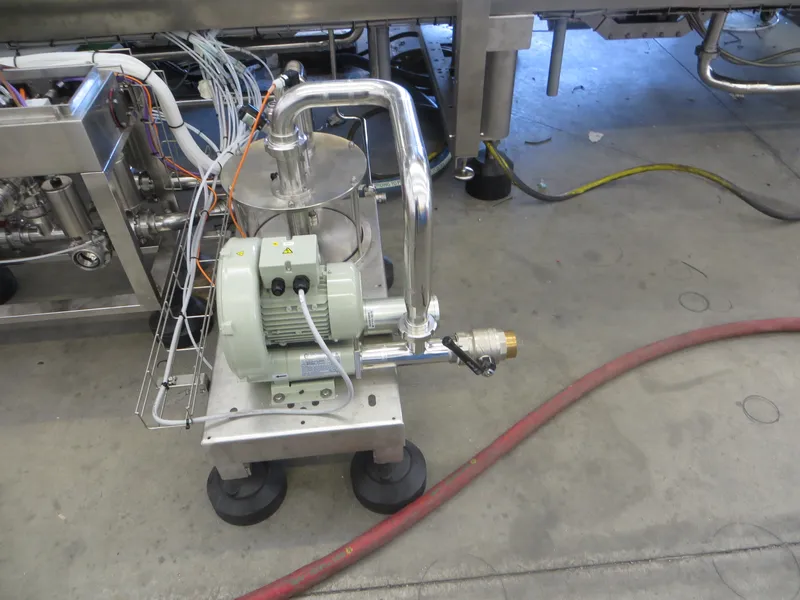

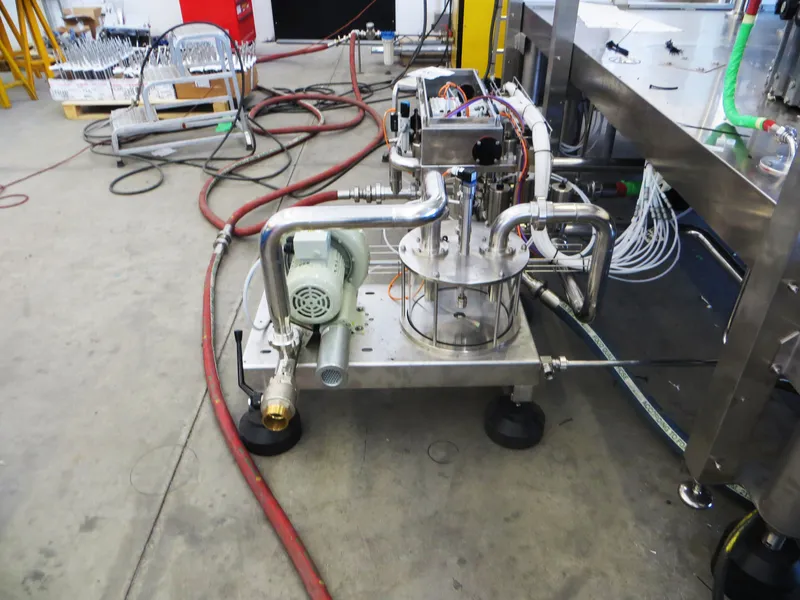

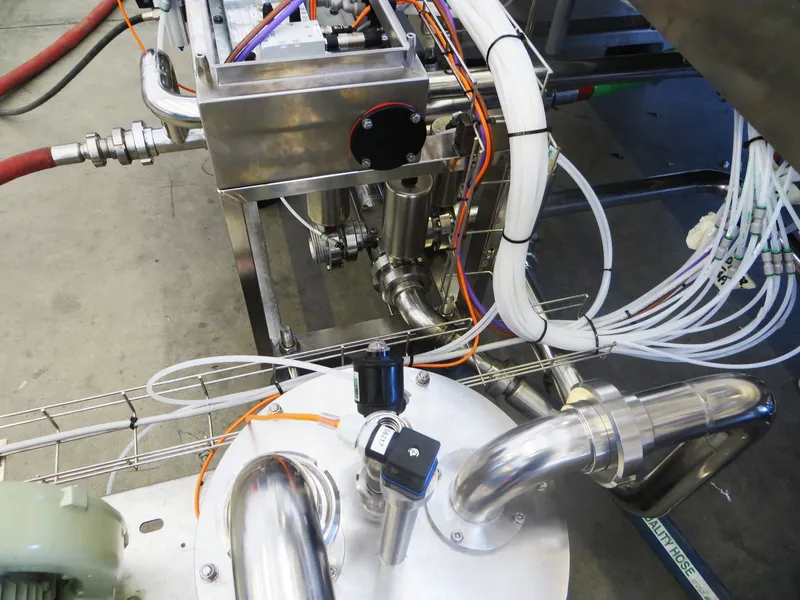

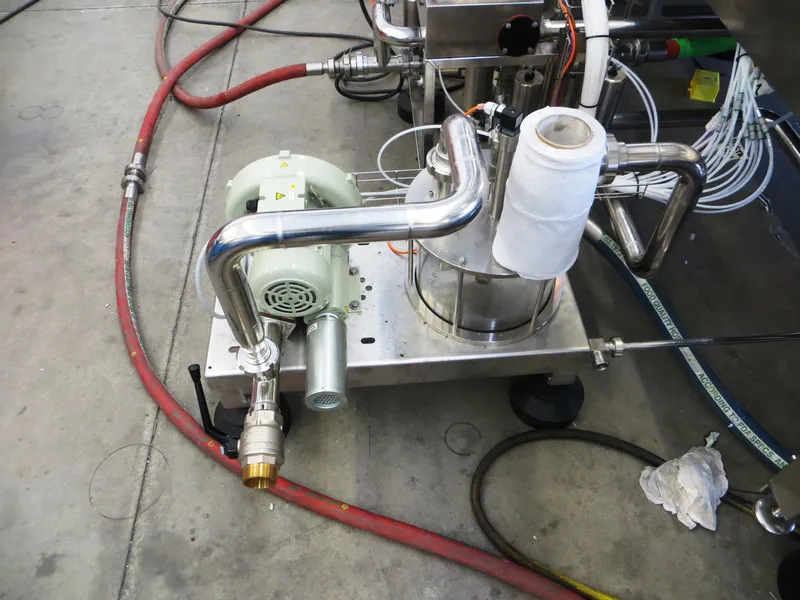

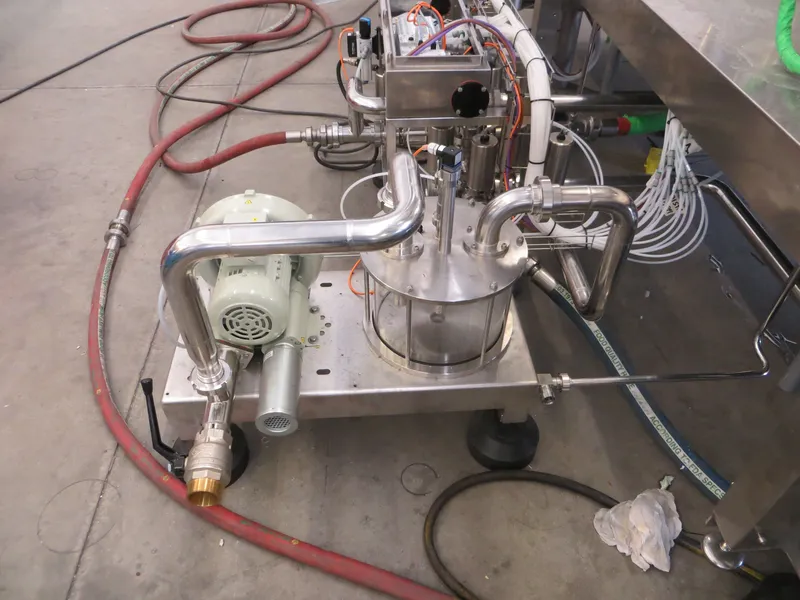

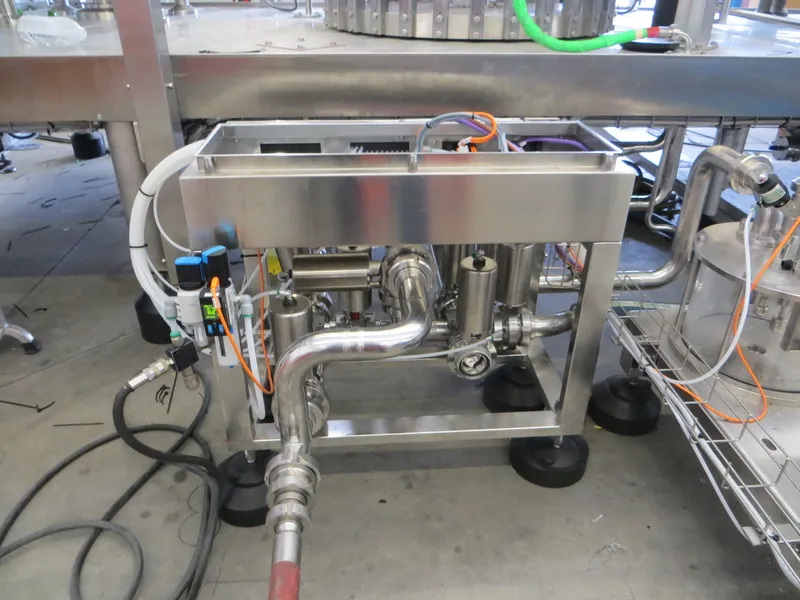

A vacuum system in the bowl consisting of a centrifuge vacuum pump, vacuometer, and valve to regulate the vacuum value

N.B.: the GLASS bottles will be handled with a low vacuum system

N.B.: the PET bottles will be handled without a low vacuum system

Electric bowl height adjustment by means of push buttons located on the machine control cabinet.

Control of the liquid level in the bowl

Liquid feeding from the bottom is controlled by a pneumatic valve activated by the level control probe.

The product flows through tubes of AISI 304 stainless steel and is conveyed into the bowl from the bottom.

Bottle lifting cylinders are made of AISI 304 stainless steel.

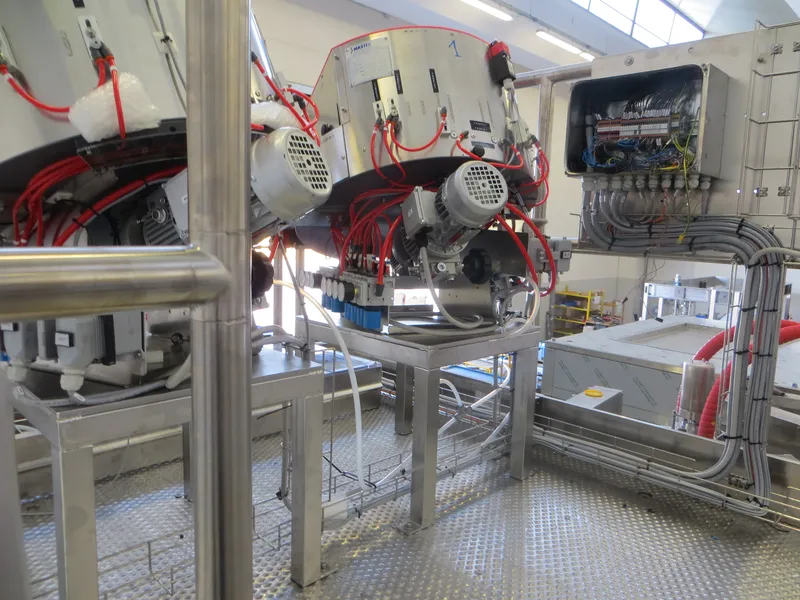

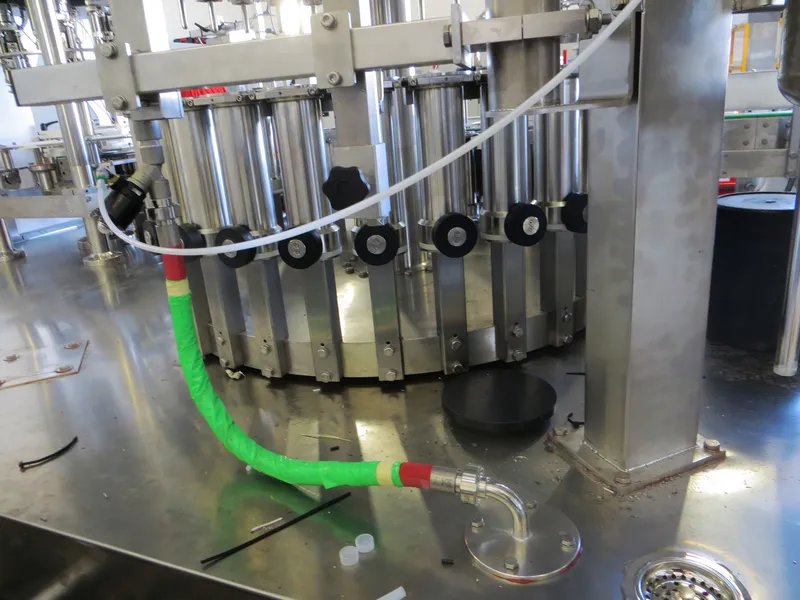

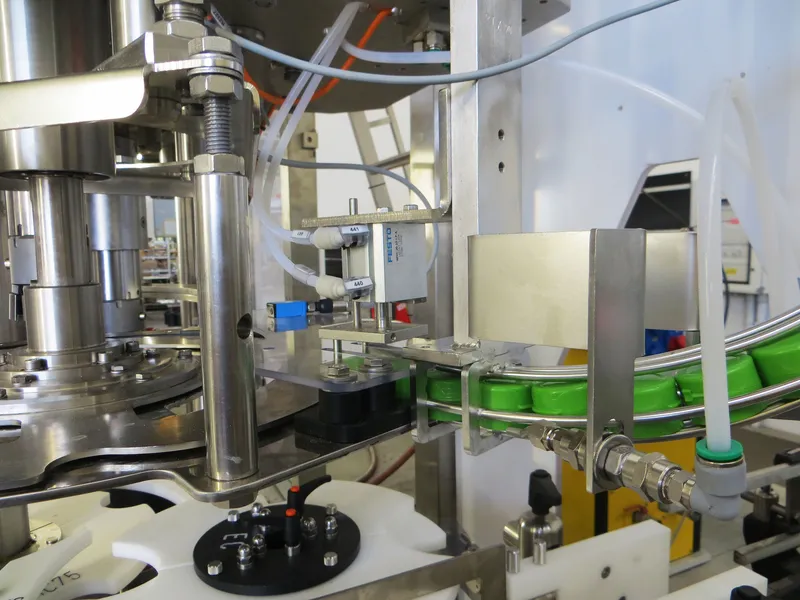

- c) Automatic capper model SIGMA/KAPPA with 4 heads to close cylindrical bottles with one side of the pilferproof aluminum screw cap, complete with pocket distributor for pilferproof aluminum screw caps and photocells to detect the cap presence in the feed chute and in the distribution throat. Electric height adjustment of the turret

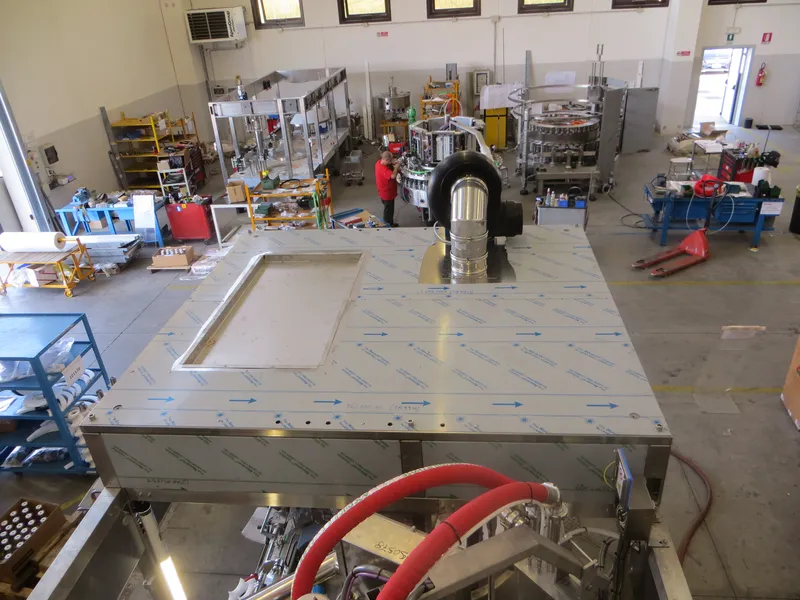

The Unibloc is further complete with:

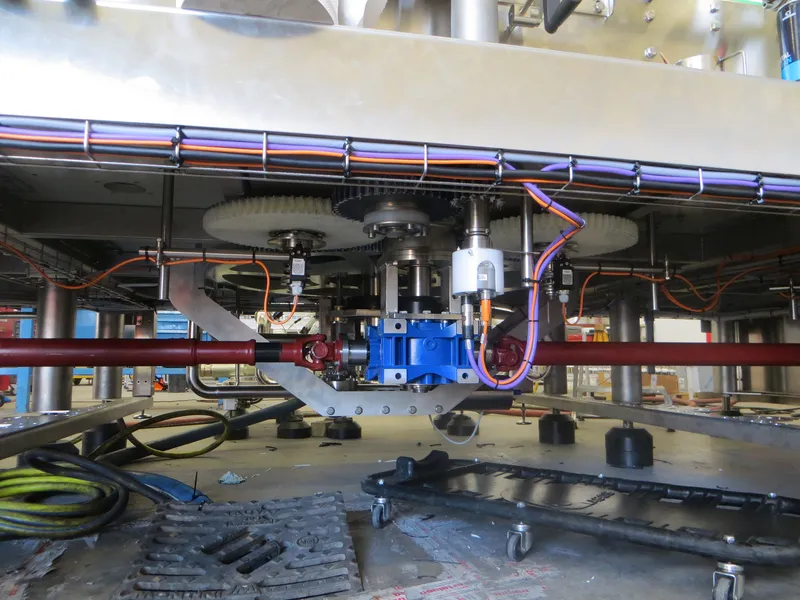

Machine support frames totally covered by stainless steel sheet cladding. The frame surrounds the mechanical gears for the machine’s movement.

Electric drive motor is widely sized, and controlled by an electronic frequency converter (inverter).

- Manual lubrication by grease nipples and atomized oil. The grease nipples of the static parts are grouped in one single spot for easy access

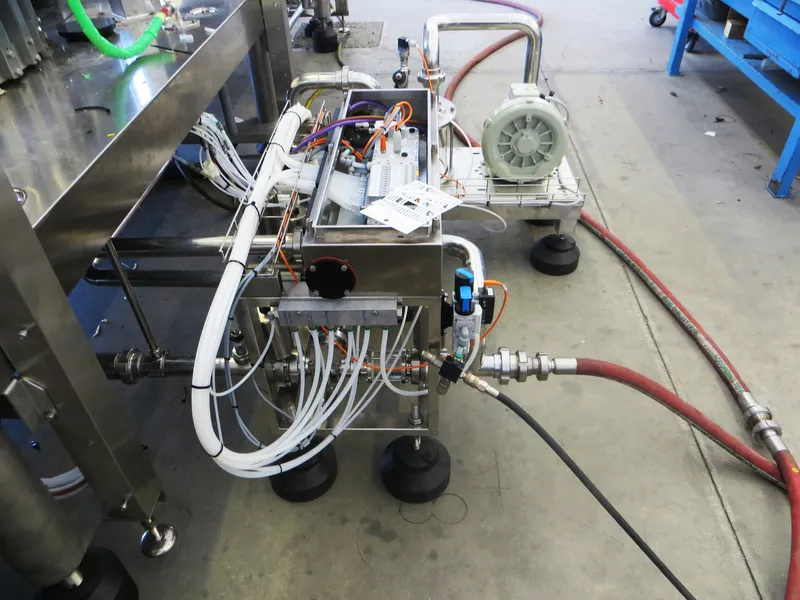

The electric control cabinet in stainless steel is located on one side of the machine. The control box surrounds:

- the PLC for the machine management

- multifunction push-button panel with digital display showing:

. the production speed

. the technical and operating parameters

. diagnostic and alarms

. machine management menu

- analogic pressure gauges.

- Safety guards made of clear panels and a stainless steel frame permit the visual inspection of the whole machine.

- Each door is equipped with a safety microswitch stopping the machine automatically when the door is opened.

- The machine is in compliance with CE work safety and health regulations.

- Set of change parts to suit one size of cylindrical bottle, composed of:

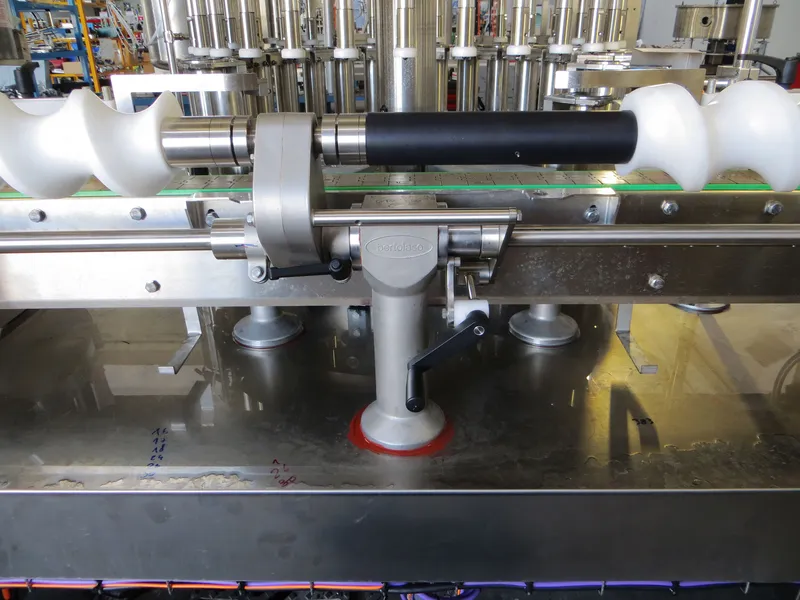

- bottle transfer system via infeed-screw

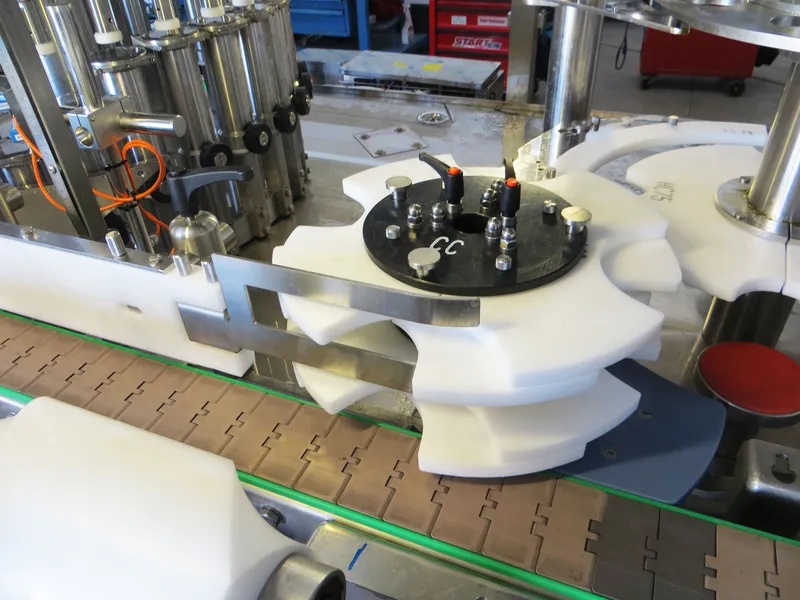

- starwheels and guides with quick-release design to be installed in a bottling line

Accessories and options of the unblock

– Unibloc is suitable to handle PET bottles on rinser, filler, and screw capper

– Two photocells to be installed at the machine inlet and two photocells to be installed at the machine outlet to monitor the bottle accumulation and to change the speed of the machine automatically according to the bottle flow.

-

- 1 Pneumatic device to stop the bottle flow at the inlet

Device for remote assistance

A thermometer is fitted on the bowl to check the product temperature.

Bottle change parts

Infeed-screw for bottles 1) and 2)

Infeed-screw for bottles 3) and 4)

Infeed-screw for bottles 5) and 6)

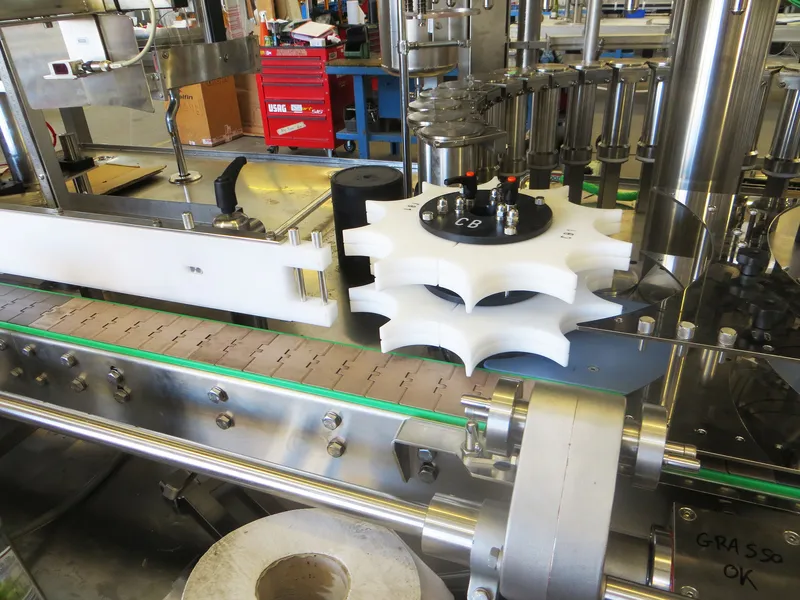

- – Adjustable starwheels (Bertolaso patent) which allow to handling of cylindrical bottles with diameters within a range of 40 mm (from 55 to 95 mm). The adjustment of the starwheel pocket width is made by activating a manual device.

- The operator only needs to replace the interchangeable profiles on the central guides when changing the bottle size; the central guides are fixed, in stainless steel, predisposed to receive the interchangeable profiles for each bottle size, and equipped with a quick coupling and release system

- – Starwheels with upper and lower pockets with independent adjustment

- Central guide with adjustable profiles to be coupled to the adjustable starwheels for a different bottle size

- Set of profiles to be coupled to the adjustable starwheels for bottles 1) and 2)

- Set of profiles to be coupled to the adjustable starwheels for bottles 3) and 4)

- Set of profiles to be coupled to the adjustable starwheels for bottles 5) and 6)

Accessories and options for the rinser

Safety pressure gauge stopping the machine in case of insufficient pressure of the rinsing liquid

- Set of gripping pads to suit a bottle neck finish or shape different from the basic format (to be confirmed after sample examination)

Predisposition of the machine for water and aggressive liquids composed of:

- Frame covered by stainless steel sheets in Aisi 316

- All the parts are in touch with the solution in stainless steel Aisi 316

- Pipes and gaskets in special material

- Electro-exhauster and upper cover of the machine

The supply doesn’t include the unit for the liquid rinsing solution

– Rinser Idra 30/1050 with fixed nozzles, suitable to carry out 2 liquid treatments

Accessories and options for the filler

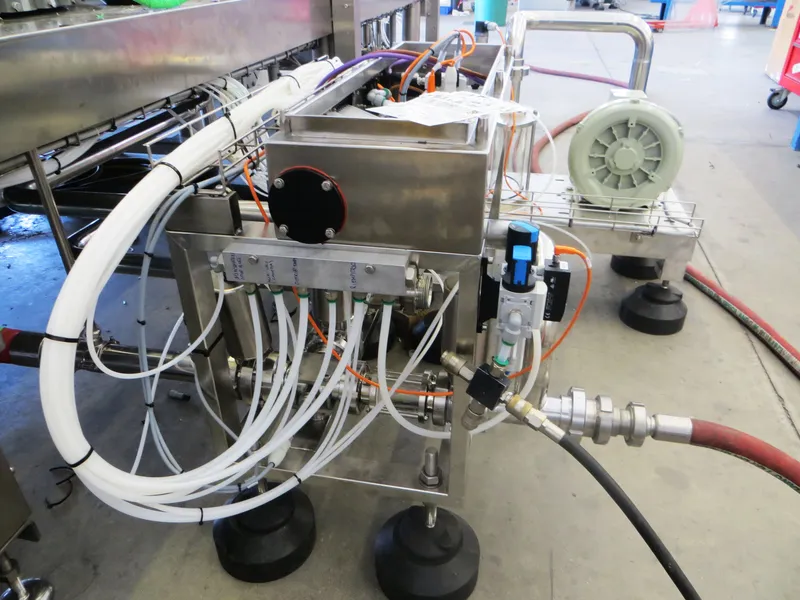

- 1 Filler in the Electro-pneumatic version. The control of the filling phases is with PLC which controls a series of valves and cylinders with electro-pneumatic operations. This system ensures the accuracy of settings regardless of speed fluctuations. The filling configuration is controlled by the PLC and can be modified through an operator panel with a wide-colored touch screen placed inboard the machine. The transmission of the data between PLC and valves placed on the filling bowl is via field bus through an electric maintenance-free manifold with non-corrosive plated slip rings.

- The electro-pneumatic version allows the filling of the GLASS bottles with low vacuum and the filling of the PET bottle by gravity

- 1 Set of centering cones on the filling valves. They permit to center perfectly the bottles under the filling valves before the fill tube penetrates into the bottleneck

- 1 Set of additional plastic reductions for the centering cones to suit a bottle neck finish or shape different from the basic format

1 Centralized operated system for the filling level regulation. The system permits modification of the length of the fill tube penetrating into the bottleneck and changes the fill level with a regulation range of a max of 80 mm. The system permits a quick bottle changeover and prevents any physical contact operator/filling valve.

- 1 Automatic system for the simultaneous opening and closing of all the filling valves.

- By pressing the push buttons on the control cabinet, the operator opens/closes the filling valves at the same time of the filling monoblock Bertolaso.

The system permits a quick and easy intervention during the bowl emptying, cleaning, and sanitizing phases and prevents any physical contact between the operator and the filling valves of the filling monoblock Bertolaso.

- 1 Predisposition of the machine for the connection with the C.I.P. cleaning and sanitation system (cleaning in place) of the syrups filling system.

- The filling monoblock Bertolaso is provided with a manifold for the distribution of the sanitizing product to all the filling valves.

- The supply includes one set of watertight dummy bottles for the recirculation of the sanitizing product.

The supply and the connection with the unit for the preparation, the heating, and the feed of the sanitizing product are not included

- 1 Set of dummy bottles in self-draining version: each dummy bottle is automatically emptied without the need for manual operator intervention to open the valve placed on the bottom of each dummy bottle of the filling monoblock Bertolaso.

- 1 Circuit for the internal cleaning of the bowl by means of spray balls designed for an energetic removal of residual thick or very sugary liquids. The tank and the pump for feeding the sanitizing liquid are not included in the supply and will be checked after the decision of the syrups filling system.

- 1 System for external washing of the filling valves by hydroalcoholic solution, complete with nozzles, valves, and tank for the filling monoblock Bertolaso.

- 1 Protection of the vacuum pump (when filling glass bottles) by means of a Pyrex tank, complete with washing spray ball, level probe, and automatic discharge in this syrups filling system.

Probe for the control of the product level in the bowl and predisposition to the connection of the probe with the inverter of the product feeding pump. The probe puts out a 4 – 20mA signal to the inverter (the supply of the inverter and pump are not included).

Accessories and options for the screw capper

Device with photocells to detect the cap presence in the feed chute and in the distribution throat

Set of accessories for the cap distribution + feed chute for aluminum screw cap (cap a) for the filling monoblock Bertolaso.

Feed chute for aluminum screw cap (cap b)

Application on the capper of a second distributor for the distribution of the pilferproof aluminum screw cap (cap c) and of the press-on plastic cap (cap d) as well. So, the capper of the filling monoblock Bertolasois equipped with a distributor for the aluminum screw caps and a distributor for the plastic caps. The supply includes stairs and walk away for the operator to perform format changeover and maintenance of accessories for the cap distribution + feed chute for pilfer-proof aluminum screw cap with pourer – Ø 31,5 x H 24 (cap f and cap g)

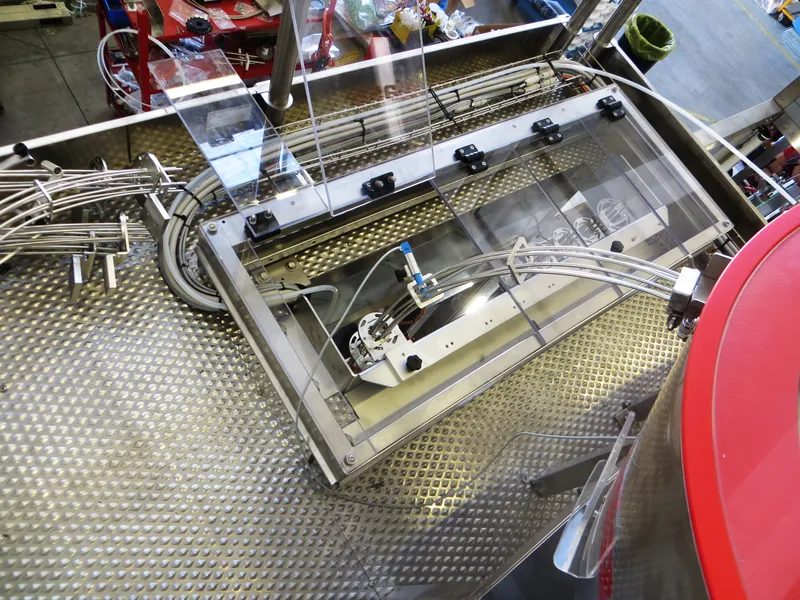

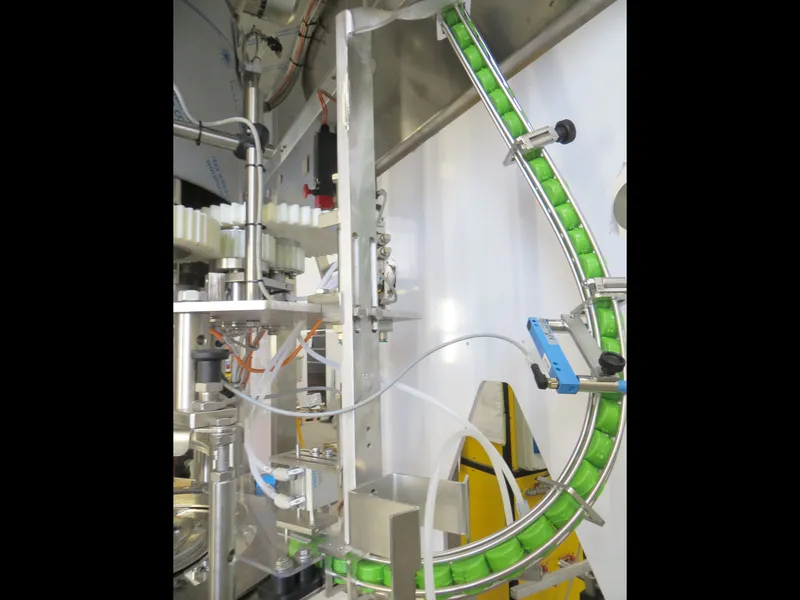

Pick and place system for the distribution of the press-on plastic cap (cap d) on the filling monoblock Bertolaso:

Capping heads with quick-release design

1 Set of heads for aluminum screw cap (cap a)

1 Set of heads for aluminum screw cap (cap b)

1 Set of heads for aluminum screw cap (cap c)

1 Set of heads with jaws for the press-on plastic cap (cap d)

1 Set of heads for aluminum screw cap (cap f and cap g)*

*Please note: only upon the final closing tests the Seller can confirm the same set of heads for both cap f) and cap g)

1 Bottle by-pass rails

1 Mechanic belt elevator model EMN, complete with stainless steel hopper and inspection port, electric variable speed drive gearmotor/ gearbox, cap elevation belt in plastic material, stainless steel electric control box, modular arm for the cap transport covered by stainless steel sheet cladding, with the reversion of direction and photocell to detect low level of caps inside the hopper

Height of elevation of the filling monoblock Bertolaso: 3500 mm

hopper capacity: 550 litres

1 Horizontal extension L = 5000 mm for the connection of the mechanic belt elevator with the cap distributor, complete with cap discharge system with belt reverse direction and cap level signal

Technical details of the filling monoblock Bertolaso

- Voltage: 380 V – 3-phases Ground+Neutral

- Control voltage: 24 V

- Frequency: 50 Hz

- Working direction: from LEFT to RIGHT (clockwise)

- Working height: 1.050 ± 50 mm

- Chain: 82,5 mm width, plastic chain, 4 mm tick

- Instruction manuals: The operating and maintenance manual in English and Hungarian languages is to be provided under separate sending via the Internet.