Description

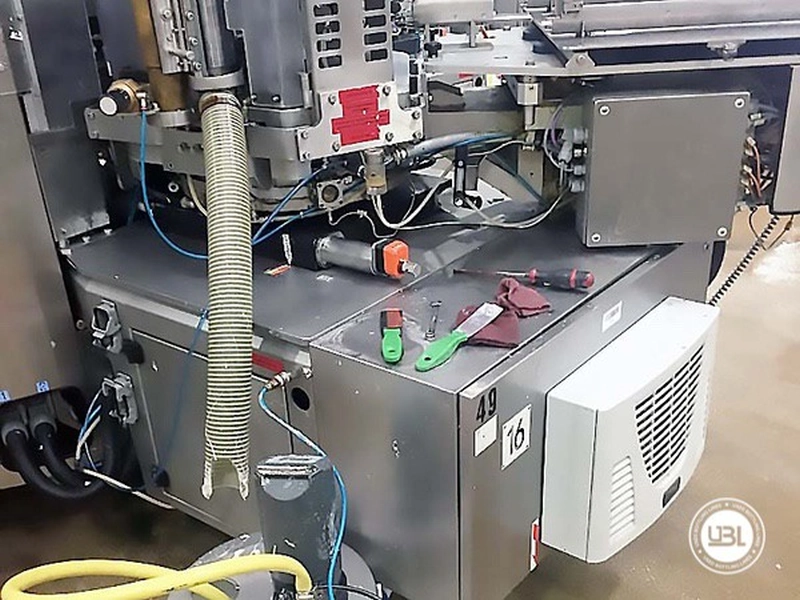

Sidel Labeller FLEXIBLE SL90 F85 64T/SM + Cold Glue 8/8/130 S3/E3

Technical Specifications of the Sidel Labeller

FLEXIBLE SL90 F85 64T/SM + Cold Glue 8/8/130 S3/E3

equipped with 3 (three) cold glue modules, to apply:

- one front body label

- one back body label

- one neck label

on the round glass bottle.

- Cold glue and/or PSL application

- Pre-cut paper and/or OPP label

- Partial label

- Glass Bottle

Bottle min/max height: 150/350 mm

Bottle min/max diameter: 50/100 mm

Label min/max height: 20/120 mm

Label min/max length: 20/130 mm

Some considerations:

Sidel Labeller was used for dedicated production, then the company decided to suspend production and therefore the machinery became available.

For information, a new machine of this kind has a purchase cost for the new one which is around 600,000 euros.

This model of Sidel labeller can apply both hot glue labels and plastic labels on reels.

It has a non-stop system to have a little leeway during high-speed production.

This used equipment is one of the examples of excellent technology that can be applied to the labelling sector.

The used Sidel Labeller machine in question can apply both wraparound and partial labels, has an electronic cam and therefore the rotation of the plate can be programmed.

Some services:

If you are interested, we can provide you with all the technical specifications of the machinery and also provide assistance for maintenance or for installation at your company. We can also help you to verify the best transport solution and to carry out the correct packing. If you desire we can also make customized equipment to process your bottles, either by reusing old ones or building new ones, depending only on your bottle size.