Machine type

Manufacturer

Model

Year

Notes

Machine type

Angled shears for body blank cutting

Manufacturer

VARIOUS BRANDS

Model

GW-3

Notes

Germany

Machine type

Body welder

Manufacturer

Soudronic

Notes

Automatic Soudronic body welder

Machine type

Body expander

Manufacturer

Bibra

Notes

Germany

Machine type

Flanger for can body ends

Manufacturer

VARIOUS BRANDS

Machine type

Bottom and lid seamer

Manufacturer

Yaguchi

Notes

Japan

Machine type

Sheet shears

Manufacturer

Cevolani

Notes

Italy

Machine type

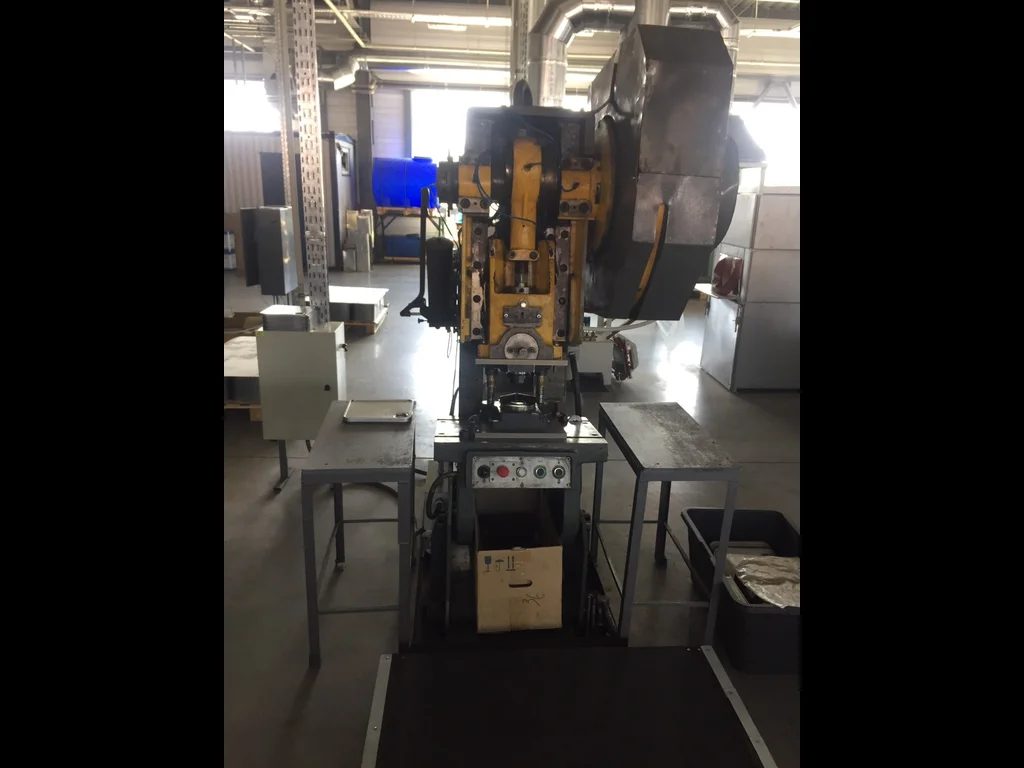

Press for ends production

Manufacturer

VARIOUS BRANDS

Model

RKHD 40

Notes

2 pcs

Machine type

Hole punching press for Bericap closure

Manufacturer

Bericap

Machine type

Semi-automatic sealing compound application machine

Manufacturer

VARIOUS BRANDS

Notes

Turkey; new

Machine type

Compound lining machine

Manufacturer

W.R. GRACE

Notes

Belgium

Machine type

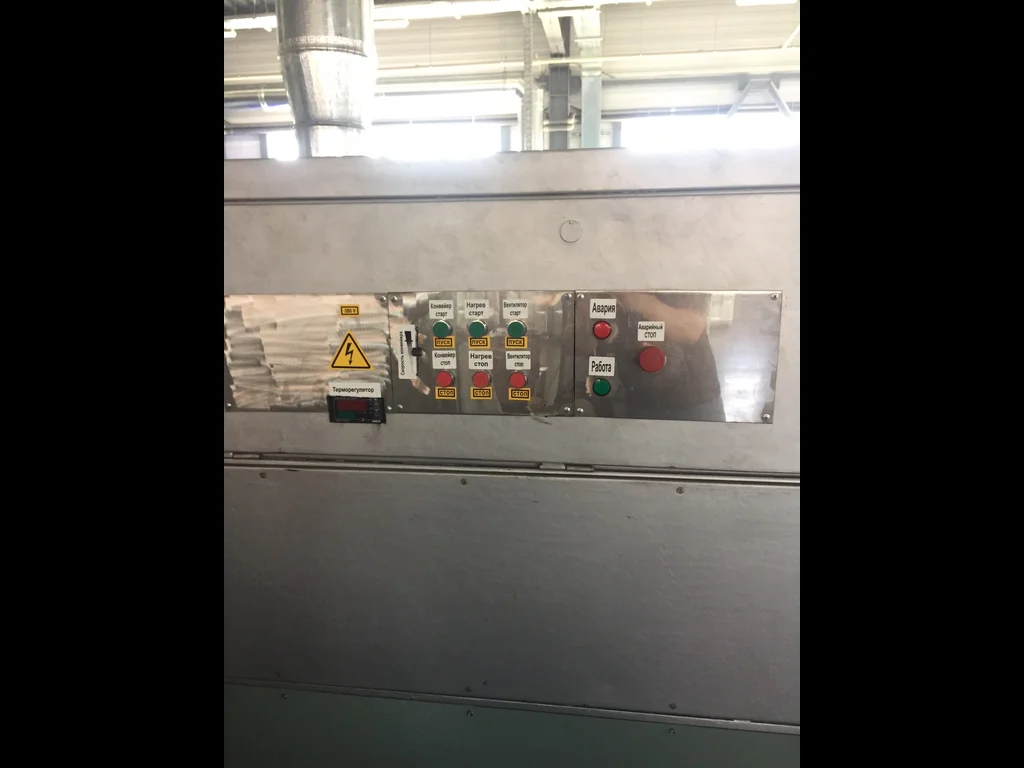

Tunnel drying oven

Manufacturer

VARIOUS BRANDS

Machine type

Semi-automatic handle welder

Manufacturer

VARIOUS BRANDS

Description

Used Complete Tinplate Can Production Line for Oil (4–20 L) – Overview

This second-hand, industrial packaging line is a complete tinplate can production system engineered for 4–20 L oil containers. Configured for body making, end making, compound lining, curing, double seaming, and handle welding, it offers a proven route to scale up edible oil container manufacturing. The line features reputable OEMs such as Soudronic, BIBRA, YAGUCHI, Cevolani, W.R. GRACE, and RKHD, making it a robust choice for companies seeking a used bottling line complement or an integrated container-making solution for food and beverage packaging operations.

Year of manufacture: 1976 (body making section built in 1981)

Technical Specifications & Performance Data

Container Range & Materials

- Format range: 4 L to 20 L tinplate steel cans for edible oil and related viscous products

- Body styles: compatible with large-format metal cans; bottom and lid closed via double seam

- Closure preparation: press station for punching pourer/spout opening compatible with Bericap-type closures

Process Flow & Included Equipment

- Sheet preparation: sheet shears (Cevolani, Italy) and angled sheet shears GW-3 (Germany)

- Body making: automatic Soudronic body welder for longitudinal seam welding

- Body sizing: BIBRA expander (Germany) for dimensional stabilization of can bodies

- End forming: machine for crimping/flanging shell ends

- End production: RKHD 40 presses (2 pcs) for can ends manufacturing

- Closure hole press: dedicated press for Bericap-type pourer hole

- Compound lining: sealing compound application machine W.R. GRACE (Belgium) + semi-automatic compound liner (Turkey, new)

- Curing: tunnel drying oven for compound curing and adhesion

- Seaming: YAGUCHI double seamer (Japan) for bottom and lid application

- Handle application: semi-automatic handle welder

Typical Output Parameters

- Nominal throughput depends on can size, seamer tooling, welding speed, and oven residence time

- Detailed performance tests and format-specific estimates can be provided upon request

Supported Products

- Edible oils (sunflower, olive, seed oils), food-grade fats

- Also suitable for non-food industrial liquids subject to appropriate compliance and compound selection

Advanced Automation & Control Systems

- Machine-level controls from OEMs (equipment runs with individual control panels; PLC-based control where supplied by manufacturer)

- Independent stations allow phased commissioning and step-by-step line balancing

- Provision for integrating line interlocks, jam detection, and status signals to a central HMI/SCADA if desired

- Process-critical stations (welder, double seamer, compound liner, oven) arranged for sequential quality assurance

Production Line Integration Capabilities

- Upstream: compatible with sheet feeding, coating/printing lines, and end stock preparation

- Downstream: integrates with oil filling/capping, labelling, case packing, and palletizing for a complete used bottling line ecosystem

- Interfaces: dry contacts or fieldbus-ready expansion (to be engineered during installation) for start/stop, fault, and safety loops

- Suitable for industrial packaging operations across food and beverage container manufacturing

Machine Condition & Maintenance History

- Year of manufacture: 1976 (body making section built in 1981)

- Condition: in storage, decommissioned and prepared for transport

- Documentation: Original user manuals are available upon request; OEM references and general operating procedures can typically be obtained from manufacturers or industry channels.

- Recommended pre-start service: inspection of weld wheels/electrodes, expander mechanics, seamer tooling and chucks/rolls, compound pump and applicators, oven conveyor/drive, and pneumatic circuits

- Spare parts/tooling: availability to be confirmed during technical audit

Operational Performance & Versatility

- Format flexibility: 4–20 L formats supported via appropriate change parts and tooling adjustment

- Quality outcomes: continuous longitudinal seam welding, precise compound application and curing, and reliable double seams on bottom and lid

- Closure readiness: integrated punch station produces lids ready for Bericap-type pour spout fitments

- Application scope: edible oils as primary target; also applicable to lubricants, chemicals, and specialty liquids subject to regulatory compliance

Installation Requirements & Site Preparation

- Power: three-phase industrial electrical supply sized to the full connected load of welder, presses, oven, and auxiliaries

- Compressed air: stable, dry air for pneumatic actuators and control valves

- Thermal utilities: curing oven requires appropriate energy source and exhaust/ventilation provisions

- Ventilation & emissions: extraction for compound lining and oven zones in accordance with local codes

- Flooring & layout: level industrial floor with adequate footprint for sheet handling, body transport, and service access

- Integration: space allocation for conveyors, guarding, QC stations (seam teardown, leak testing) as required

Safety Standards & Compliance Certification

- Safety equipment: legacy guarding and emergency stops should be reviewed; additional perimeter guarding, interlocks, and safety PLCs may be required for full compliance

- Compliance: buyer should perform a complete risk assessment and bring the line into conformity with applicable regulations (e.g., Machinery Directive/CE or local equivalents)

- Process safety: ensure proper ventilation and handling for sealing compounds (water- or solvent-based), thermal safeguarding of the oven, and lockout/tagout procedures

- Food-contact considerations: select approved compound and implement hygiene and traceability procedures for edible oil packaging

Component Summary for Quick Reference

- Soudronic automatic body welder

- BIBRA expander (Germany)

- Shell end crimping/flanging machine

- YAGUCHI double seamer for bottom and lid (Japan)

- Presses for end production: RKHD 40 (2 pcs)

- Press for punching Bericap-type closure hole

- Sheet shears: Cevolani (Italy)

- Angled sheet shears: GW-3 (Germany)

- Sealing compound application: W.R. GRACE (Belgium) + semi-automatic unit (Turkey, new)

- Tunnel drying oven

- Semi-automatic handle welder