Filling Monoblock

Ref: M218Rinser

Filler

Capper

Related machines

Interested in this machine?

Used Filling Monoblock for Beer Comac 2014

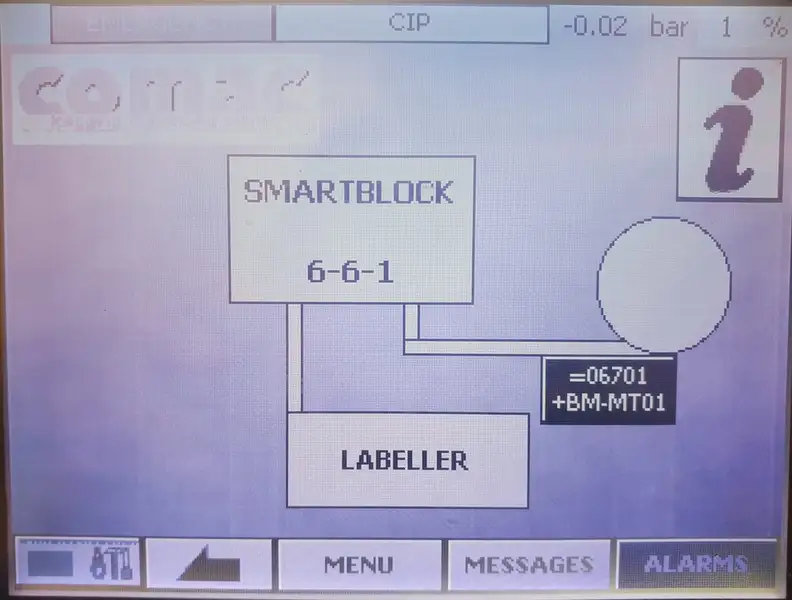

For those in the market for a used filling monoblock for beer, consider this Comac 6/6/1 model from 2014. This machine is capable of producing up to 700 bottles per hour and is designed specifically for glass containers. The available formats for this machine are 0.33 L and 0.50 L, and it is meant for filling beer.

The rinser on this machine features six grippers and a single treatment cycle, which helps to efficiently clean and prepare the bottles for filling. The filler has six valves and operates using an isobaric fill type, which means that the pressure in the bottle is equal to the pressure in the filling tank. This ensures that the beer is filled evenly and at the correct pressure. The filler also features a fixed type of nozzle and a traditional isobaric valve.

The capper on this machine is designed specifically for crown caps and features one head, with cap sizes of 26 e 29. This machine is designed to rotate clockwise and has a total of 82 machine hours logged. It is currently ready for operation and features safety features to ensure the safety of operators.

Technical specifications

Manuals are included with this machine, which can be useful for operators who need to troubleshoot issues or perform maintenance tasks. The electrical data for the machine is V: 400 • kW: 50 • Hz: 2.2, which indicates the voltage, power, and frequency requirements for the machine.

In addition to the filling monoblock, this machine also comes equipped with a double-sided adhesive labeling machine for cylindrical bottles. The labeling machine comes with a collection table to make the process more efficient.

Overall, this Comac 6/6/1 filling monoblock is a great choice for those in the market for a used beer filling machine. Its isobaric fill type ensures even and accurate filling of beer in glass containers, and its crown cap capper makes it an ideal choice for bottling beer. The included labeling machine adds even more value to this machine and makes it a versatile addition to any beer bottling operation.